task:

information center and observation platform for the construction of terminal T3 at Frankfurt Airport

client:

Fraport AG

procedure type:

planning study, 2009

cooperation:

netzwerkarchitekten | echo))) kommunikation im raum |

size:

64.000 sqm

technical planner:

club L94 (landscape planning) | Dr. Kreutz und Partner (structural engineer) |

visualization:

netzwerkarchitekten | echo))) kommunikation im raum |

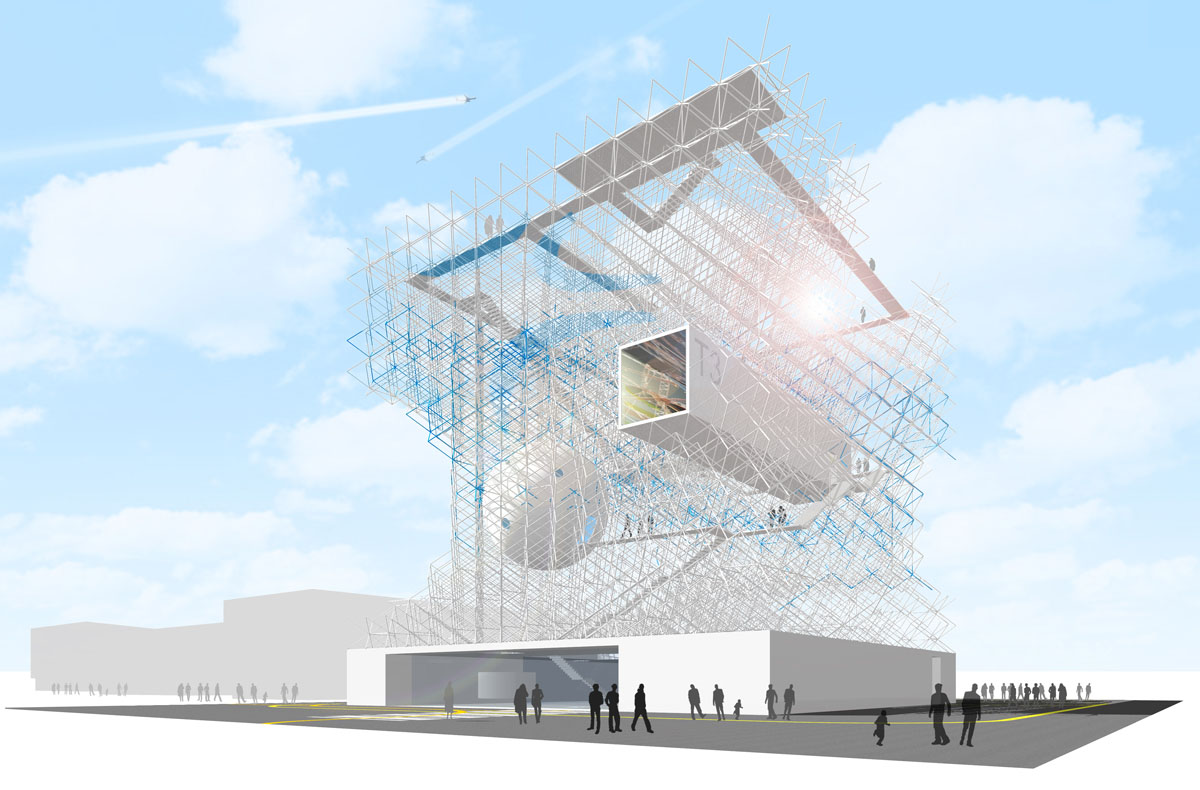

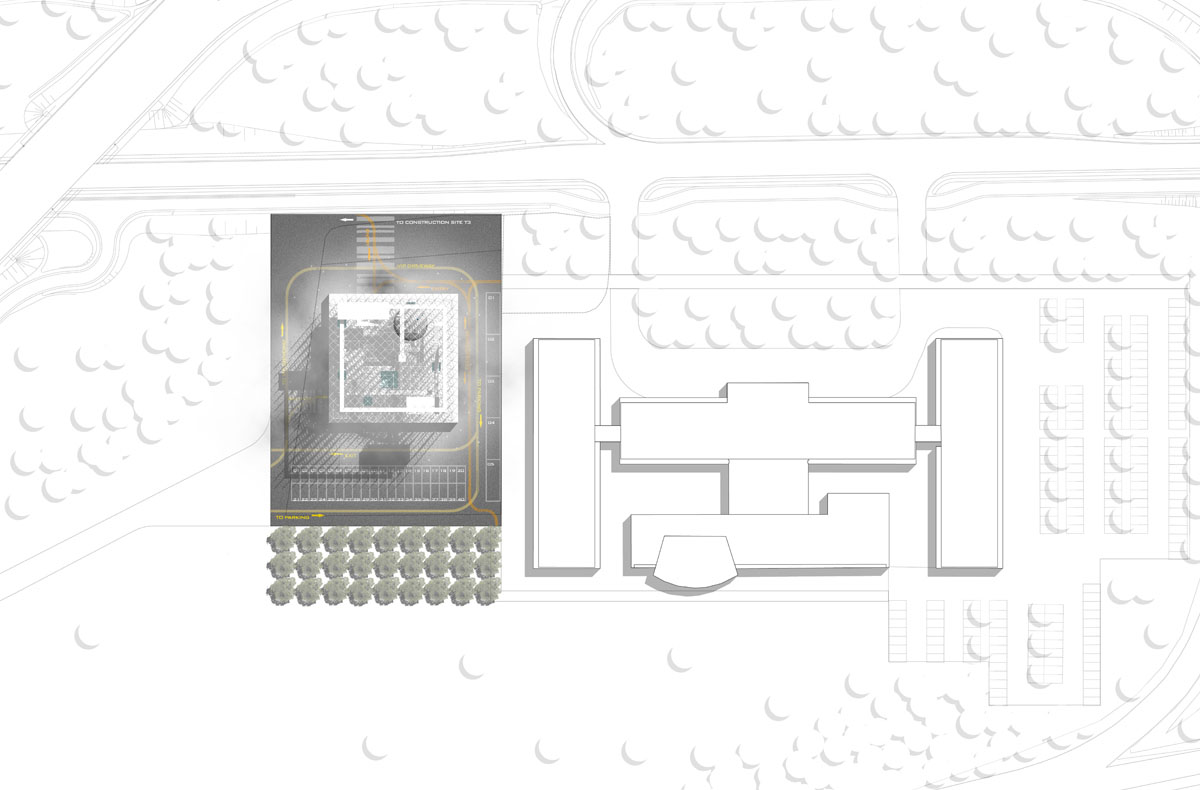

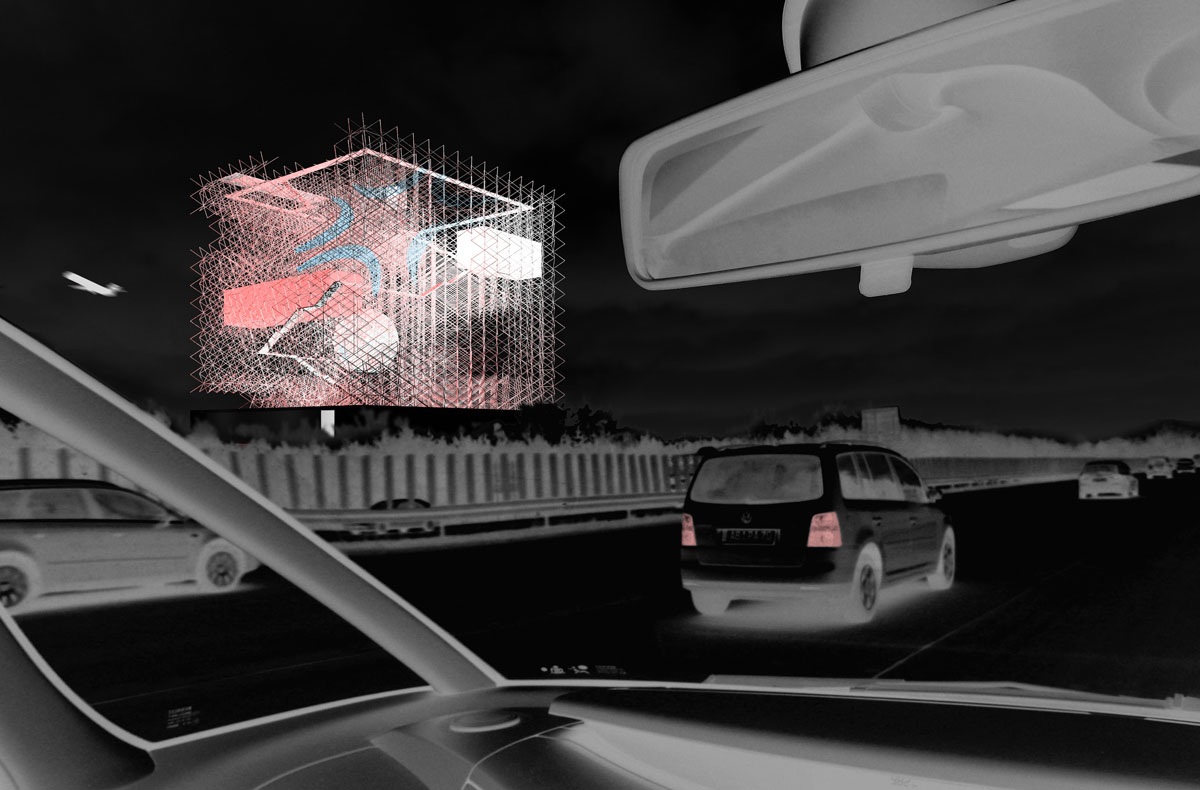

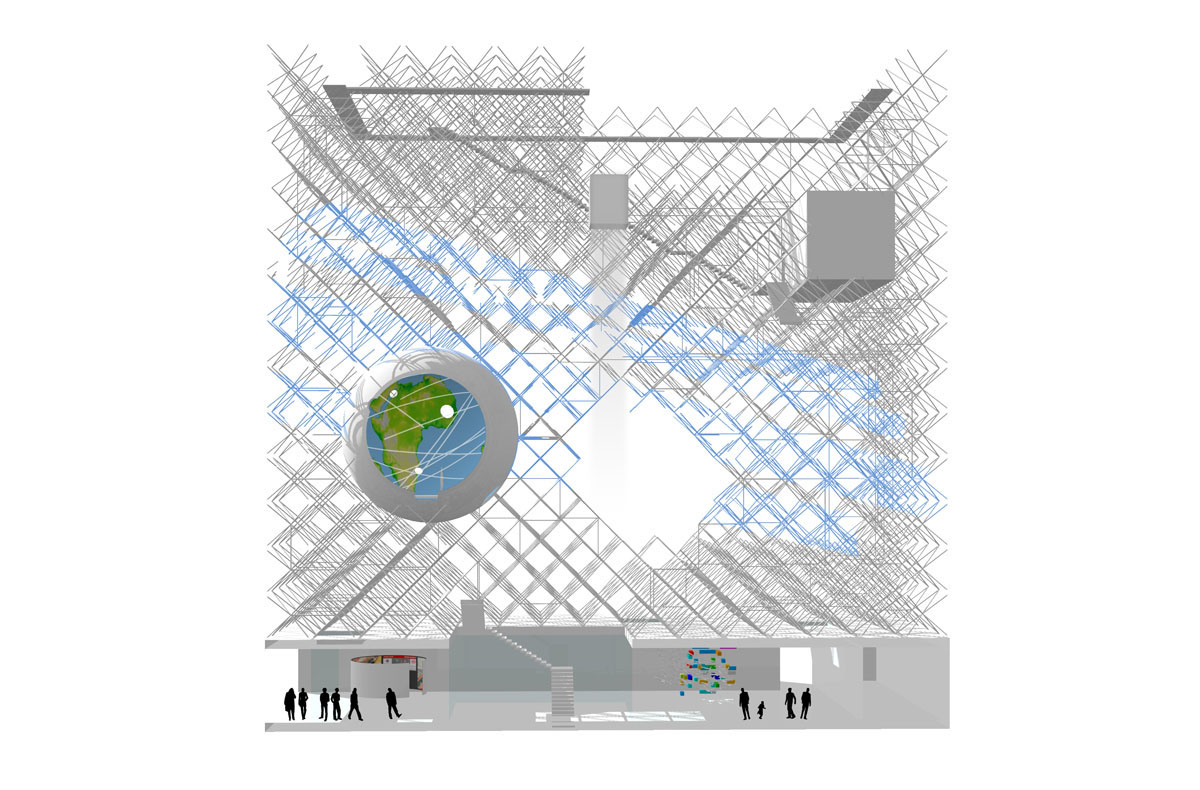

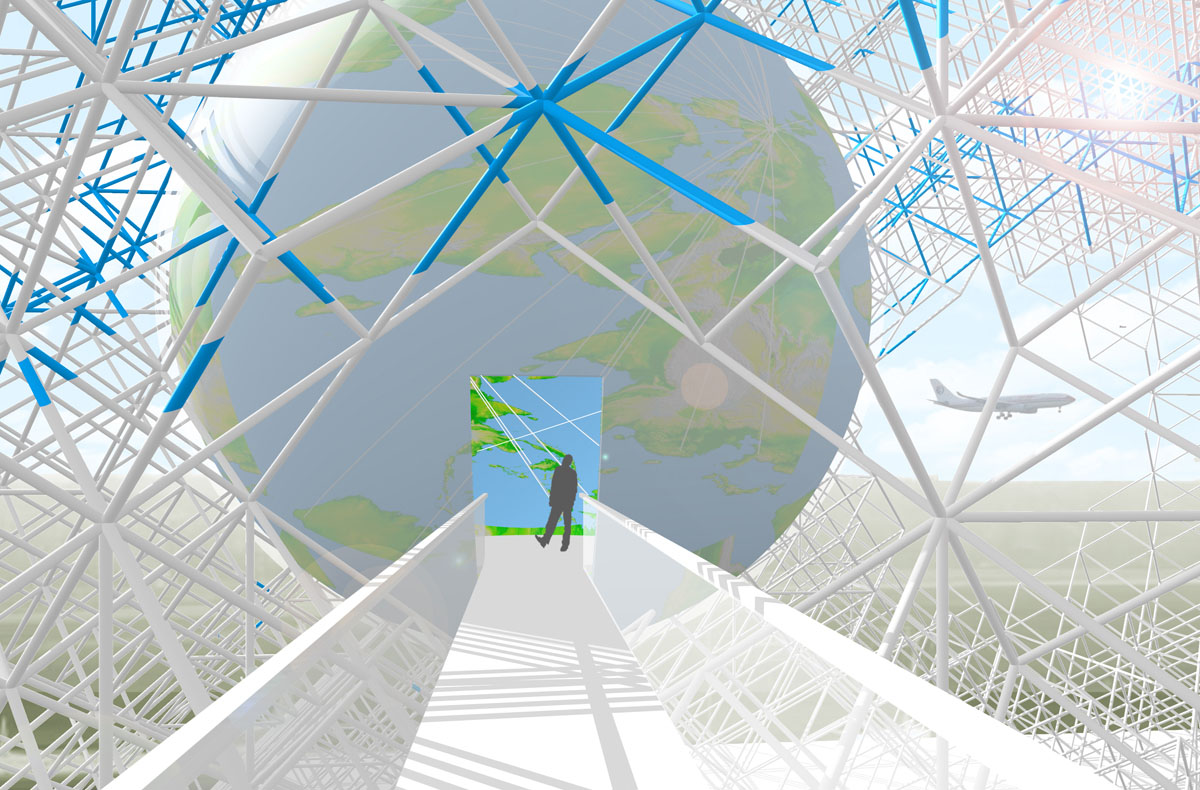

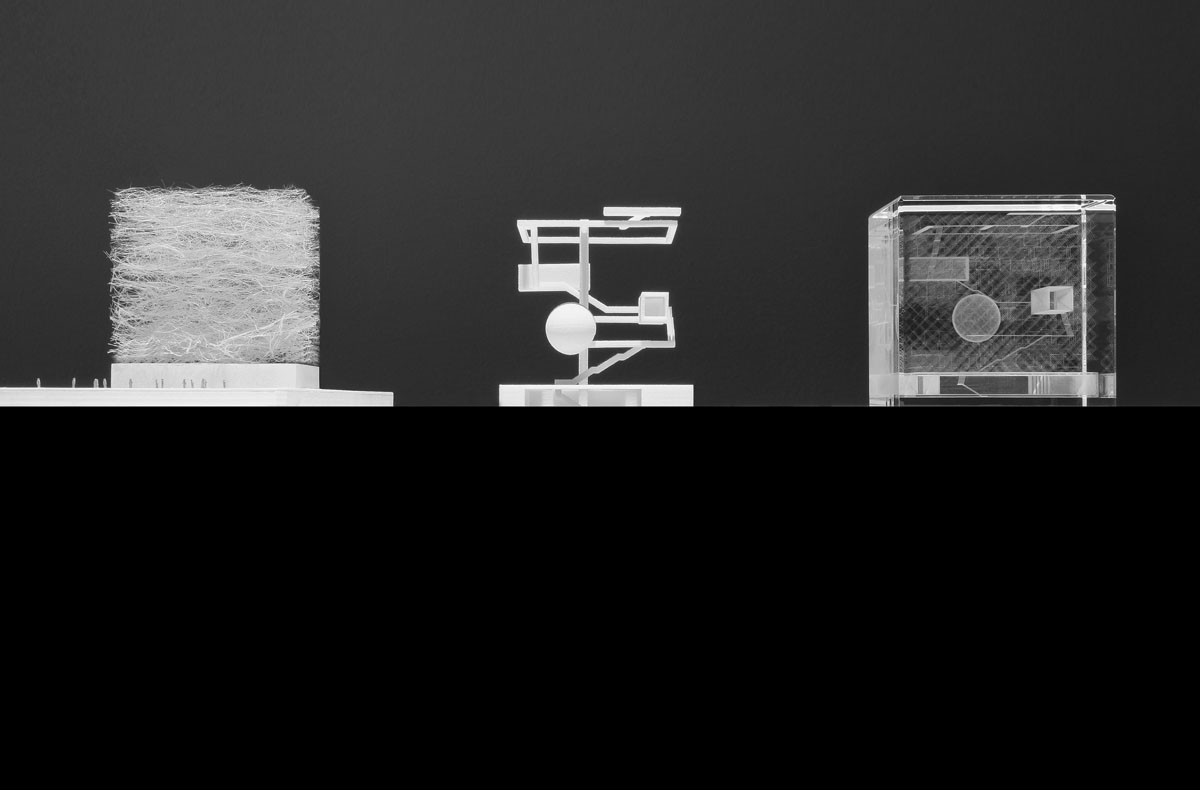

The proposed design for an Information Center and observation platform at Terminal T3 at Frankfurt Airport presents itself as a widely visible, floating and transparent cloud in a cubic form. The load-bearing structure of the building is divided into two areas: the one-story base and the overhead cloud framework.

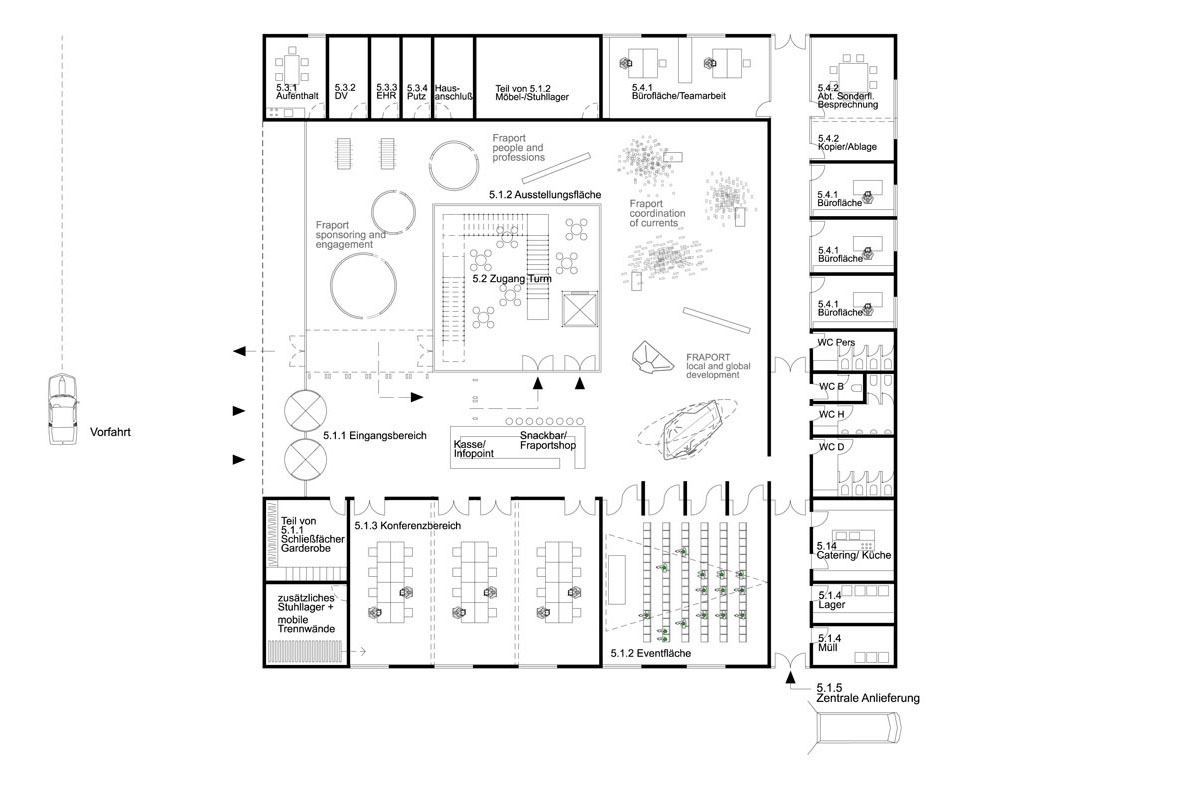

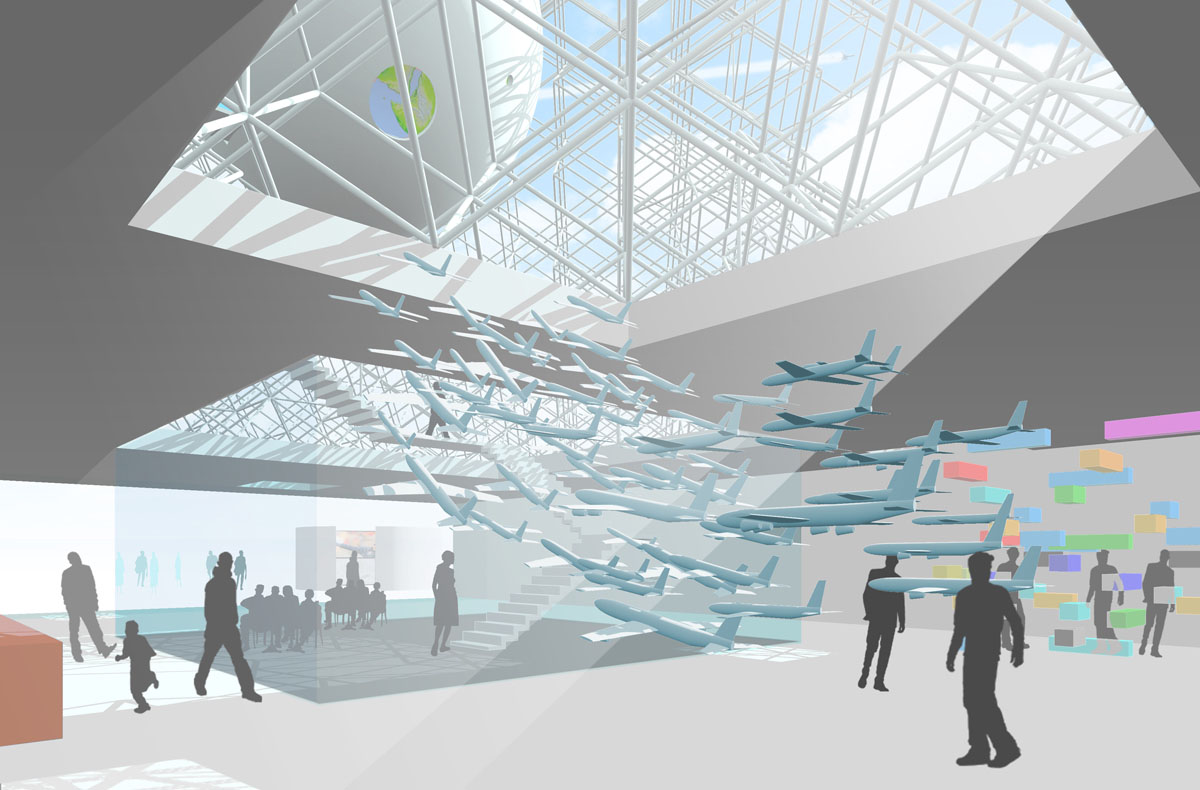

The one-story base, with its entrance to the west toward the airport, houses all customer services, and is organized around a central atrium with an open roof providing access to the upper cloud structure. The building uses extensive windows, along with the atrium, to introduce natural light. Navigating the building is easy due to the openness and the visual cues provided. The movement around the building creates the impression of a pulsating airspace in which air flows in the body. There, references and graphic effects are built up.

Stairs rise from the main floor through the atrium roof to the platform framework above. Various platform areas, stairs, and foot bridges within the upper level framework provide a 360° view. Three unheated exhibition rooms provide an atmospheric short impression of the Fraport world on the way up to the platform, which can be booked for exclusive use.

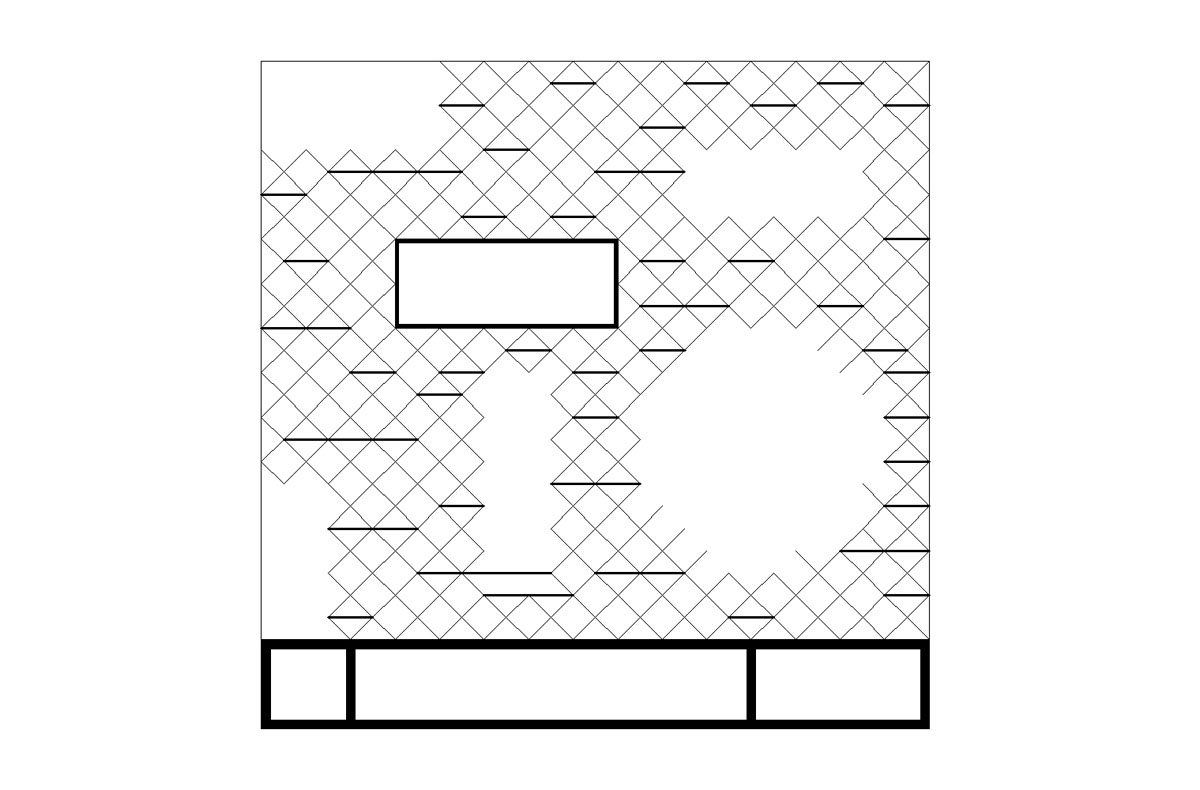

The main struts of the open framework are arranged at 45° angles. The orthogonal arrangement of the main struts ensures as uniform a load distribution as possible. In the areas where deviation forces are created in the orthogonal main grid by cutout spaces or rims, additional horizontally-positioned rods are arranged to ensure the load transfer in the entire structure. These seemingly randomly arranged additional rods provide the desired local densities of the support structure. The optimization and the load distributions in the structure are controlled by the number and the local arrangement of the horizontal bars.

The proposed design for an Information Center and observation platform at Terminal T3 at Frankfurt Airport presents itself as a widely visible, floating and transparent cloud in a cubic form. The load-bearing structure of the building is divided into two areas: the one-story base and the overhead cloud framework.

The one-story base, with its entrance to the west toward the airport, houses all customer services, and is organized around a central atrium with an open roof providing access to the upper cloud structure. The building uses extensive windows, along with the atrium, to introduce natural light. Navigating the building is easy due to the openness and the visual cues provided. The movement around the building creates the impression of a pulsating airspace in which air flows in the body. There, references and graphic effects are built up.

Stairs rise from the main floor through the atrium roof to the platform framework above. Various platform areas, stairs, and foot bridges within the upper level framework provide a 360° view. Three unheated exhibition rooms provide an atmospheric short impression of the Fraport world on the way up to the platform, which can be booked for exclusive use.

The main struts of the open framework are arranged at 45° angles. The orthogonal arrangement of the main struts ensures as uniform a load distribution as possible. In the areas where deviation forces are created in the orthogonal main grid by cutout spaces or rims, additional horizontally-positioned rods are arranged to ensure the load transfer in the entire structure. These seemingly randomly arranged additional rods provide the desired local densities of the support structure. The optimization and the load distributions in the structure are controlled by the number and the local arrangement of the horizontal bars.